-40%

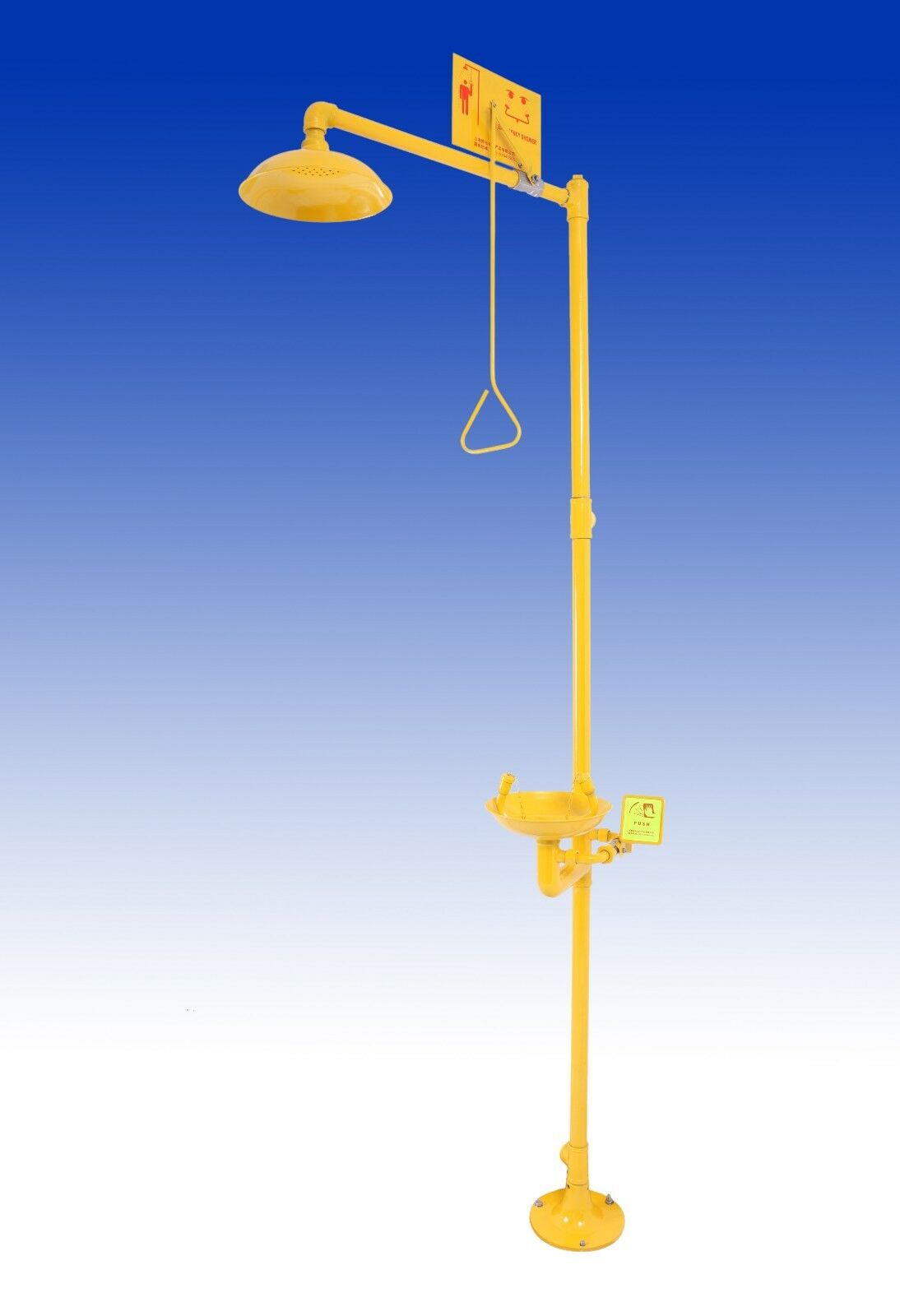

eye wash station cum shower emergency eyewash stainless steel ABS coating

$ 178.99

- Description

- Size Guide

Description

Operating standards: conformed to US ANSI Z358.1-2009 requirements (standards).Passed SGS pre-shipment inspection before

Material: 304 stainless steel for most parts

Emergency shower eye : stainless steel 304 inlet pipe (1-1/4),Stay-open ball balve switch, pull rod (D8mm)&shower head

Eye wash : stainless steel 304 inlet pipe, stay - open ball valve switch & eye wash bowl

Eye spray head : stainless steel, built-in chemical resistant PP

Coating: yellow ABS coating, corrosion resistant

Water source: drinking water

Items

Inspection items and units

Spec

1

Material

The stainless steel compound eye washer is made of 304 stainless steel with corrosion resistance and high quality (with a nickel content of more than 8)

2

Spray height (mm)

2340

3

flow rate (L)

120-180

4

eye wash nozzle height (mm)

1010

5

eye wash nozzle flow (L)

9-18L

6

open to the water outlet time (s)

<=1

7

sealing experiment (MPA)

0.5

8

working pressure (MPA)

0.25

9

drainage outlet size

5/4’’

10

Eye washing system and shower system water inlet size

5/4’’

1. Why are emergency showers or eyewash stations important?

Emergency showers and eyewash stations can help workers to flush away hazardous substances that can cause injury.The first 10 to 15 seconds after exposure to a hazardous substance, especially a

corrosive substance, are critical. Delaying treatment, even for a few seconds, may cause serious injury.

2. Where are emergency showers or eyewash stations required?

Work areas and operations that may require these devices include:

Battery charging areas

Laboratories

Spraying operations

High dust areas

Dipping operations

Hazardous substances dispensing areas

3. What type of equipment should I choose?

Emergency showers are designed to flush the user's head and body. They should not be used to flush the user's eyes because the high rate or pressure of water flow could damage the eyes in some

instances.

Eyewash stations are designed to flush the eye and face area only.

There are combination units available that contain both features: a shower and an eyewash.

4. How to use them in emergency situation?

1. To use emergency eye wash:

Immediately flush eyes for at least 15 minutes.

Keep the eyes open and rotate the eyeballs in all directions to remove contamination from around the eyes. An injured person may need help holding the eyelids open.

Seek for medical care or see a doctor for further assistance

2. To use emergency shower:

Immediately flush the affected area with copious quantities of water for at least 15 minutes. Protect the eyes from inadvertent contamination.

Remove contaminated clothing, jewelry, and shoes. Use a clean lab coat to provide the victim with privacy and warmth.

Seek for medical care or see a doctor for further assistance

Why choose us?

Our emergency shower and eyewashes are produced far above ANSI Z358.1stanadards and passed SGS on-site goods inspection. For standard models, safety stock is available for your urgent order.

Ours: Eye wash flow rate at 12~18L/Min. It's adjustable and can support enough water under low water pressure.

Shower flow rate at 120~180L/Min, further exceeding ANSI standards >= 75.7L/Min